Banner making - VLB layout

Banner Making: From Envision to Completion

VINYL BANNER LAYOUT:

If for example, we were producing a vinyl lettered banner seen below,

These are the steps we would follow:

Artwork Requirements

First, and most importantly we would determine whether or not we can make a vinyl lettered banner with the given artwork. As mentioned in the earlier section, vinyl banners can only be produced directly from artwork in vector based format. Consequently, if the artwork provided is a raster or bitmapped format, it would then be reworked to a vector graphic to make computer cut vinyl lettering possible. This means the banner shop producing your banner would require a graphic artist to draw a duplicate of the artwork to meet vector specifications. Many customers with raster artwork that have gradients and shades of color will find it benefical, and in many cases cheaper, to have the banner digitally printed directly from the raster image instead.

Determining the correct banner size

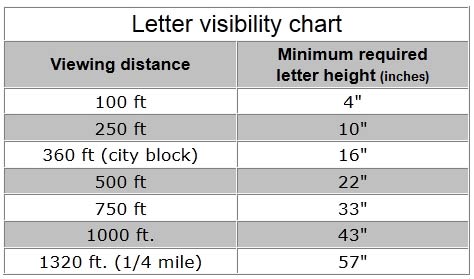

The next step is to determine the size of the banner that is needed to make it effective. The banner size depends on factors such as limits on the amount of space available; distance from the intended reader (see our visibility /readability chart below); and ultimately your banner making budget. After this determination of banner size is made, the layout of the acual banner can be finalized by making the banner shape match the shape proportions of the artwork. By examining our artwork above, we can see that the proportion of the artwork is approximately 4 times wider than it is tall. Let's say that we determined that we want our banner to be 10' wide (120" wide). Since we know that the width is four times wider than the height, we can calculate that the height will be approximately 30" tall by deviding the required banner width of 120" by the aspect ratio of 4.

VISIBILITY/READABILITY CHART:

Vinyl cutting

The next step is to design the artwork in our banner making software. We layout the banner or scale up the artwork to its full size once it is imported to this program. Next we send the paths of the vector arwork one color at a time to the plotter that will cut the vinyl. Sheets of adhesive backed vinyl for each color are loaded into our vinyl cutting equipment and cutting begins in the following manner:

- First we would cut … All the text that is in blue from our blue vinyl material.

- Next we would cut … The price in red from our red vinyl material.

- Then we would weed ... Once the letters and numbers are cut, we would weed away all the extra material, and place a very light adhesive backed transfer tape layer over the lettering to be able to apply to the white vinyl banner.

- Finally, we would place … The blue vinyl layer would be applied first and then, in the open space to the right of the text "from", we would place the red vinyl layer of the price.

Banner material

In this case of this banner we want our vinyl graphics on a white banner at a finished size of 120" x 30". So we would cut our white banner material 1" larger on all four sides to 122" x 32". This added material allows us to fold back 1" of banner material, when making a double stitched hem on all four sides, resulting in a finished size of 120" x 30". For installation purposes is is good to add grommets (brass eyelets) in each corner and every 2 - 3 feet along the top and sides on teh vinyl banner. This is done before the vinyl lettering is applied, only after it is re-measured, cleaned and prepared for vinyl application.

Placing the lettering

One of the benefits of vector art is the software recognizes shapes and lines rather than a bitmap. This allows the banner maker to scale the graphic to the chosen banner size without sacrificing resolution or image quality. Measurements between graphical objects in a vector file remain in constant proportion, thus measurements of vinyl placement are given by the artwork. These measurements are transferred to the banner material, utilizing the method of taping (explained in the next section) to maintain the original spacing and layout.